Change Language :

Filling systems

Overview

Our modular rotary and linear bearing technology can be installed in any beverage bottling line, regardless of whether it is a partially or fully automated system. The top priority for these components is that they are easy to clean, do not require lubricants and fulfil high service life requirements.

Products used and application examples

The following shows the main areas of application for our linear and plain bearing technology in filling systems. These are used in a wide variety of sections, e.g. in the clamping star for holding the bottles or in the filling and dosing station.

Customer application examples

Hygienic bearing in capping unit

KHS relies on particularly hygienic special bearings for the linear stroke in the capping units of a PET bottle filling line.

Go to user report

Injection moulding clamping star in filling line

The MultiGuide Base from Krones eliminates the need to change the clothing. Clamps and rollers are special parts, while the plain bearings are made of iglidur® X.

Go to user report

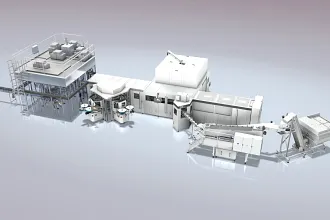

PET filling system with lubrication-free bearings

The compact filling system "InnoPET TriBlock" from KHS works with our plain, linear, ball bearings and linear tables.

Go to user report

Beverage bottling plant

For more than twenty years, plain bearings from the igus® construction kit have been used in the customised bottling plants of Küppersbusch GmbH.

Go to user report

Sterile filling line

This pharmaceutical filling line relies on lubrication- and maintenance-free drylin® storage technology.

Go to user report

Bottle leveller in bottling plant

iglidur® bearings work wear-resistant, lubricant- and maintenance-free in beverage bottling.

Go to user report

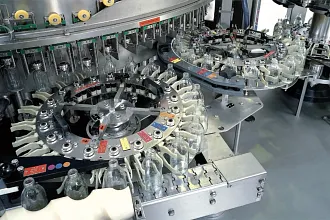

Clamping stars in filling machines

Two-component plastic rollers for clamping stars double the downtime of filling machines.

Go to user report

And even more...

Discover even more successful applications in the beverage, food and packaging industries.

Discover more applicationsConsulting

I look forward to answering your questions

LLC "Hennlich Ukraine" (Distributor)+38 044 500 58 73Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr